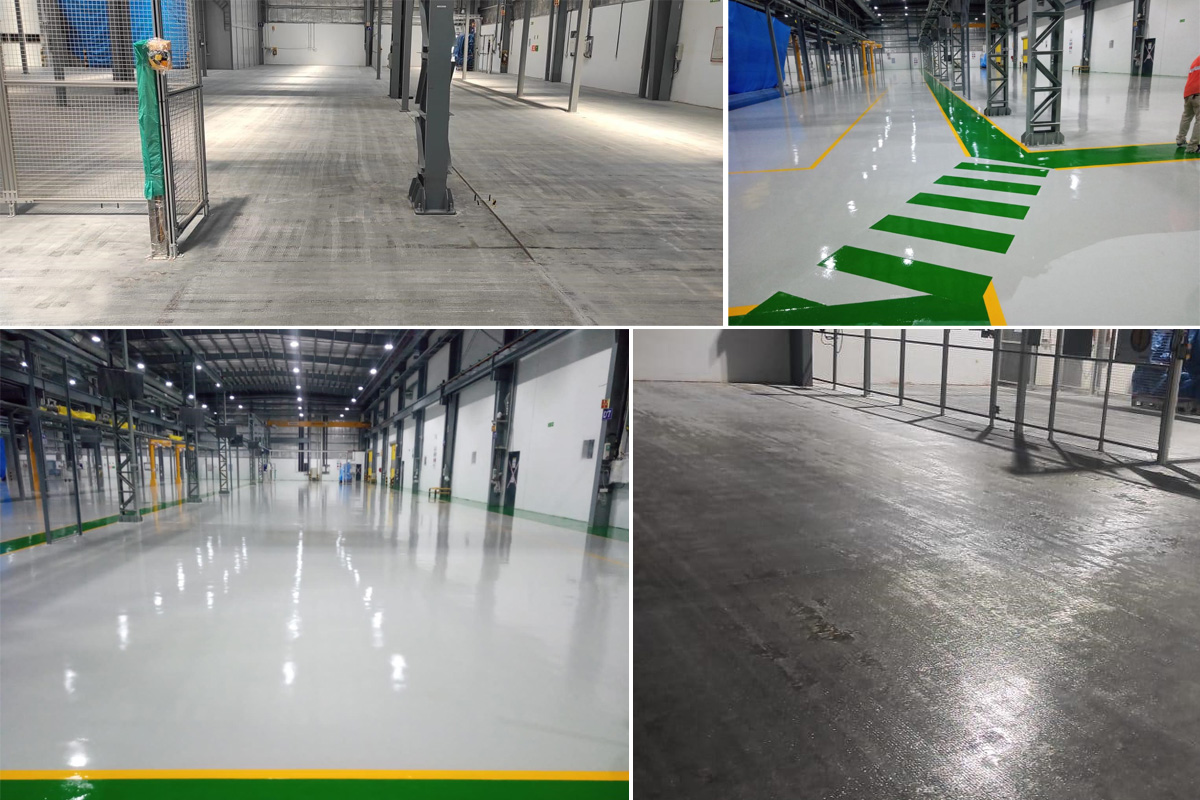

Polished floor refurbishing with PU cement composite (PUCC)

Polished concrete floor for an industrial application is well established and widely accepted. It serves to provide a durable smooth surface, capable of withstanding static and dynamic loads, suitable for many different industrial facilities.

It lacks performance attributes such as jointless, seamless surface, chemical resistance, smooth movement of trolleys and forklifts, torques associated with rotating machinery and may not completely prevent dust generation.

Hence, when an industrial client wanted a floor that can provide all of the above performance characteristics, Neocrete suggested its Neocrete HDF.

What made Neocrete stand apart from their competitors is their understanding of polished concrete and what needs to be done to ensure adhesion of PUCC with the existing surface.

The sequence of application procedure;

- Scarifying the surface to provide mechanical key

- Application of Neoflor Primer-S, a unique epoxy primer to provide high level of adhesion

- Spreading of 50-80 gsm glass mesh cloth over the primed surface in wet condition and allowed to dry overnight

- Apply one more coat of Neoflor Primer-S followed by quartz broadcasting and allowed to dry

- Remove excess sand, cut grooves as per spec, and apply 2mm scratch coat of Neocrete HDF to obtain jointless, seamless base surface

- After curing for overnight, apply 3mm thick Neocrete HDF as wear-resistant top coat.

After completing yellow line marking as per customer’s requirements, one coat of silicon-epoxy hybrid sealer is applied to obtain stain & oil resistant floor.

1. Scarifying the surface to provide mechanical key

2. Application of Neoflor Primer-S, a unique epoxy primer to provide high level of adhesion

3. Spreading of 50-80 gsm glass mesh cloth over the primed surface in wet condition and allowed to dry overnight

4. Apply one more coat of Neoflor Primer-S followed by quartz broadcasting and allowed to dry

5. Remove excess sand, cut grooves as per spec, and apply 2mm scratch coat of Neocrete HDF to obtain jointless, seamless base surface

6. After curing for overnight, apply 3mm thick Neocrete HDF as wear-resistant top coat.

7. After completing yellow line marking as per customer’s requirements, one coat of silicon-epoxy hybrid sealer is applied to obtain stain & oil resistant floor.

FINISHED FLOOR